Introduction, history and classification on Internal Combustion engines:

INTRODUCTION OF INTERNAL COMBUSTION ENGINE:

The internal combustion engine is a heat engine that converts chemical energy

in a fuel into mechanical energy, which is used for performing the mechanical work.

Chemical energy of the fuel is first converted to thermal energy by means of combustion or oxidation with air inside the engine. This thermal energy raises the

temperature and pressure of the gases within the engine, and the high-pressure gas

then expands against the mechanical mechanisms of the engine. This expansion is

converted by the mechanical linkages of the engine to a rotating crankshaft, which is

the output of the engine. The crankshaft, in turn, is connected to a transmission

and/or power train to transmit the rotating mechanical energy to the desired final

use. Cars, trucks, airplane, 2-wheelers, 3-wheelers etc. are the few common example of movable applications where as other applications include stationary engines to drive generators or pumps, and portable engines for things like chain saws and lawn mowers.

Most internal combustion engines are reciprocating engines having pistons

that reciprocate back and forth in cylinders internally within the engine. Reciprocating engines can have one cylinder or many, up to 20 or more. The

cylinders can be arranged in many different geometric configurations. Sizes range

from small model airplane engines with power output on the order of 100 watts to

large multi-cylinder stationary engines that produce thousands of kilowatts per

cylinder.

There are so many different engine manufacturers, past, present, and future,

that produce and have produced engines which differ in size, geometry, style, and

operating characteristics that no absolute limit can be stated for any range of engine

characteristics (i.e., size, number of cylinders, strokes in a cycle, etc.). This article will

work within normal characteristic ranges of engine geometries and operating parameters, but there can always be exceptions to these.

EARLY HSTORY:

Early development of modern internal combustion engines occurred in the latter half of the 1800s and coincided with the development of the automobile. Most of these early vehicles were

steam-driven prototypes which never became practical operating vehicles. Technology, roads, materials, and fuels were not yet developed enough. Very early examples

of heat engines, including both internal combustion and external combustion, used

gun powder and other solid, liquid, and gaseous fuels. Major development of the

modern steam engine and, consequently, the railroad locomotive occurred in the latter half of the 1700s and early 1800s. By the 1820s and 1830s, railroads were present

in several countries around the world.

During the second half of the 19th century, many different styles of internal combustion engines were built and tested. These engines operated with variable success and dependability using

many different mechanical systems and engine cycles.

The first fairly practical engine was invented by J.J.E. Lenoir (1822-1900).

During the next decade, several hundred of these engines were built with power up to about 4.5 kW and

mechanical efficiency up to 5%. In 1867 the Otto-Langen engine, with efficiency improved to about 11%, was

first introduced, and several thousand of these were produced during the next

decade. This was a type of atmospheric engine with the power stroke propelled by

atmospheric pressure acting against a vacuum.

Nicolaus A. Otto (1832-1891) and

Eugen Langen (1833-1895) were two of many engine inventors of this period.

During this time, engines operating on the same basic four-stroke cycle as the

modern automobile engine began to evolve as the best design. Although many people were working on four-stroke cycle design, Otto was given credit when his

prototype engine was built in 1876. In the 1880s the internal combustion engine first appeared in automobiles.

Also in this decade the two-stroke cycle engine became practical and was manufactured in large numbers.

By 1892, Rudolf Diesel (1858-1913) had perfected his compression ignition

engine into basically the same diesel engine known today.

This was after years of

development work which included the use of solid fuel in his early experimental

engines. Early compression ignition engines were noisy, large, slow, single-cylinder

engines. They were, however, generally more efficient than spark ignition engines. It

wasn't until the 1920s that multi cylinder compression ignition engines were made

small enough to be used with automobiles and trucks.

ENGINE CLASSIFICATIONS:

Internal combustion engines can be classified in a number of different ways on the basis of cycle operation in cylinder, types of fuel, method of supply of fuel, type of ignition, etc.

1. Basic Design:

(a) Reciprocating: Engine has one or more cylinders in which pistons reciprocate back and forth. The combustion chamber is located in the closed end

of each cylinder. Power is delivered to a rotating output crankshaft by

mechanical linkage with the pistons.

(b) Rotary: Engine is made of a block (stator) built around a large non-concentric rotor and crankshaft. The combustion chambers are built into the

nonrotating block.

2. Engine Cycle:

(a) Four-Stroke Cycle: A four-stroke cycle experiences four piston movements over two engine revolutions for each cycle.

(b) Two-Stroke Cycle: A two-stroke cycle has two piston movements over one

revolution for each cycle.

Three-stroke cycles and six-stroke cycles were also tried in early engine development

3. Valve Location:

(a) Valves in head (overhead valve), also called I Head engine.

(b)Valves in block (flat head), also called L Head engine. Some historic

engines with valves in block had the intake valve on one side of the cylinder and the exhaust valve on the other side. These were called T Head

engines.

(c) One valve in head (usually intake) and one in block, also called F Head

engine; this is much less common.

4. Types of Ignition:

(a) Spark Ignition (SI): An SI engine starts the combustion process in each

cycle by use of a spark plug. The spark plug gives a high-voltage electrical discharge between two electrodes which ignites the air-fuel mixture in the

combustion chamber surrounding the plug. In early engine development,

before the invention of the electric spark plug, many forms of torch holes

were used to initiate combustion from an external flame.

(b) Compression Ignition (CI): The combustion process in a CI engine starts

when the air-fuel mixture self-ignites due to high temperature in the combustion chamber caused by high compression.

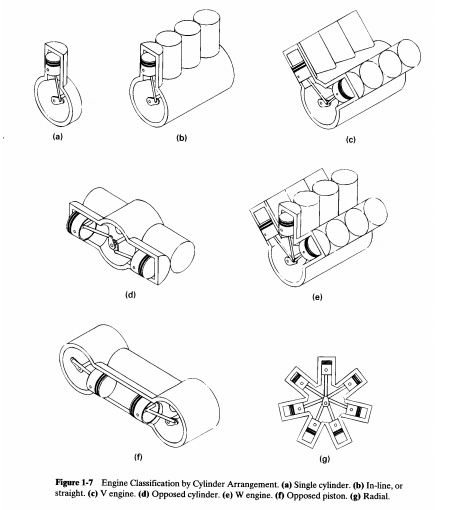

5. Position and Number of Cylinders of Reciprocating Engines

(a) Single Cylinder: Engine has one cylinder and piston connected to the

crankshaft.

(b) In-Line: Cylinders are positioned in a straight line, one behind the other

along the length of the crankshaft. They can consist of 2 to 11 cylinders or

possibly more. In-line four-cylinder engines are very common for automobile and other applications. In-line six and eight cylinders are historically

common automobile engines. In-line engines are sometimes called straight

(e.g., straight six or straight eight).

(c) V Engine: Two banks of cylinders at an angle with each other along a single crankshaft. The angle between the banks of cylinders can be anywhere

from 15° to 120°, with 60°-90° being common. V engines have even numbers of cylinders from 2 to 20 or more. V6s and V8s are common

automobile engines, with V12s and V16s (historic) found in some luxury

and high-performance vehicles

(d) Opposed Cylinder Engine: Two banks of cylinders opposite each other on

a single crankshaft (a V engine with a 180°V). These are common on small aircraft and some automobiles with an even number of cylinders from two

to eight or more. These engines are often called flat engines (e.g., flat

four).

(e) W Engine: Same as a V engine except with three banks of cylinders on the

same crankshaft. Not common, but some have been developed for racing

automobiles, both modern and historic. Usually 12 cylinders with about a

60° angle between each bank

(f) Opposed Piston Engine: Two pistons in each cylinder with the combustion

chamber in the center between the pistons. A single-combustion process

causes two power strokes at the same time, with each piston being pushed

away from the center and delivering power to a separate crankshaft at each

end of the cylinder. Engine output is either on two rotating crankshafts or

on one crankshaft incorporating complex mechanical linkage.

(g) Radial Engine: Engine with pistons positioned in a circular plane around

the central crankshaft. The connecting rods of the pistons are connected to

a master rod which, in turn, is connected to the crankshaft. A bank of cylinders on a radial engine always has an odd number of cylinders ranging

from 3 to 13 or more. Operating on a four-stroke cycle, every other cylinder fires and has a power stroke as the crankshaft rotates, giving a smooth

operation. Many medium- and large-size propeller-driven aircraft use

radial engines. For large aircraft, two or more banks of cylinders are

mounted together, one behind the other on a single crankshaft, making

one powerful, smooth engine. Very large ship engines exist with up to 54

cylinders, six banks of 9 cylinders each.

6.Air Intake Process:

(a) Naturally Aspirated: No intake air pressure boost system.

(b) Supercharged: Intake air pressure increased with the compressor driven off of the engine crankshaft.

(c) Turbocharged: Intake air pressure increased with the turbine-compressor driven by the engine exhaust gases.

(d) Crankcase Compressed: Two-stroke cycle engine which uses the crankcase as the intake air compressor.

Limited development work has been done on design and construction of four-stroke cycle engine with crankcase compression.

7.Fuel Type:

(a) Gasoline (or petrol).

(b) Diesel oil (light, high speed diesel oil etc.) or fuel oil.

(c) compressed natural gas (CNG).

(d) liquified petroleum gas (LPG).

(e) alcohol (methanol, ethanol)

(f) Dual fuel and multi fuel engines have also been developed.

8.Method of fuel input for S.I engine:

(a) carbureted type:

(b) Multipoint Port Fuel Injection: One or more injectors at each cylinder intake.

(c) Throttle Body Fuel Injection: Injectors upstream in intake manifold.

9. Types of Cooling:

(a) water cooled:

(b) air cooled:

10. Application:

(a) Automobile, Truck, Bus.

(b) Locomotive.

(c) Stationary.

(d) Marine.

(e) Aircraft.

(f) Small Portable, Chain Saw, Model Airplane.

Excellent content. Thanks for sharing!!

ReplyDelete