VALVE TIMING OF 4-STROKE PETROL (SI) AND DIESEL ENGINE (CI)

Valve Timing of Petrol Engine (SI)

Valve timing is the regulation of the points in the cycle at which the valves are set to open and close. We can easily explain valve open and closing through the valve timing diagram. The exact moment at which the inlet and outlet valve opens and closes with reference to the position of the piston and crank shown diagrammatically is known as the valve timing diagram. It is expressed in terms of degree crank angle.

If we consider the ideal cycle, inlet, and exhaust valves open and close at dead centers. But in an actual cycle, they open or close before and after dead centers. Valve timing has to be adjusted according to the speed of the engine.

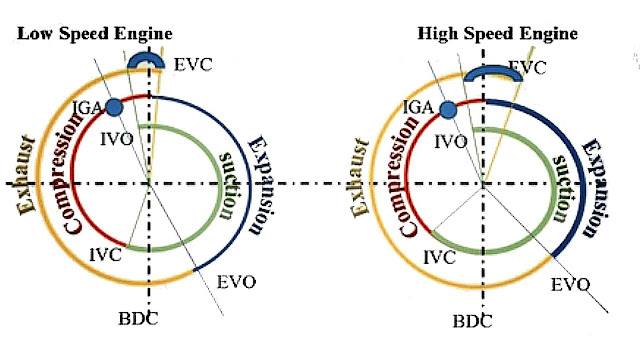

A typical valve timing diagram for the slow and high-speed petrol engine is shown in fig.

|

|

Low-Speed Engine |

High-Speed Engine |

|

TDC- Top Dead Centre |

|

|

|

BDC- Bottom Dead Centre |

|

|

|

IVO- Inlet Valve Open |

10 degree TDC |

10 degree TDC |

|

IVC- Inlet Valve Close |

20-25 degree after BDC |

40-50 degree after BDC |

|

EVO- Exhaust Valve Opens |

25 degree before BDC |

45 degree before BDC |

|

EVC- Exhaust Valve Close |

5 degree after TDC |

20 degree after TDC |

|

IGA- Ignition Advance. |

15 degree before TDC |

40 degree before TDC |

Reasons for actual valve timing:-

1. Mechanical Factor: -The clearance

2. Dynamic Factor: - The actual valve timing is set taking into considering the dynamic effects of gas flow.

Intake Valve Timing:

Intake Valve Open :

To begin with, inlet valve timing, let us see both low speed and high-speed SI engines fig below

As we can see in the above figure that for both low speed and high speed engine the intake valve open 10 degrees before the arrival of the piston at TDC on the exhaust stroke. This is to ensure that the valve will be fully open and the fresh charge starting to flow into the cylinder as soon as possible after TDC. Due to the effect of inertia and time required to attain the full opening, the inlet valve opens somewhat earlier than at TDC, so that by the time the piston reaches TDC the inlet valve is fully open.

Intake Valve Close :

The closing of the inlet valve takes place during the start of the compression stroke (i.e. when the piston move from BDC to TDC after finishing suction stroke and the starting of compression stroke). If the inlet the valve is allowed to close exactly at BDC then less charge than the capacity enters during the suction stroke so the inlet valve closing is delayed to 20°-25 degrees after the crank reaches the BDC position during slow speed and 40-50 degrees after the crank reaches the BDC position during high speed.

Exhaust valve Timing:

Exhaust Valve Open :

The exhaust valve opens at the end of the expansion stroke. The exhaust valve opening is done before the piston reaches the BDC so as to provide more time for all the burnt gases to escape. The opening of the exhaust valve is necessary because if there are some burnt up gases left in the cylinder it may affect the cylinder walls and the spark plug. So the exhaust valve is opened 30-35 degrees before BDC for slow speed and 45-50 degrees before BDC for high speed.

Exhaust Valve Close :

The exhaust valve closing is also important to let out all the burnt gases. The time between the exhaust valve opening and the exhaust valve closing determines the amount of burnt gases that escape. Usually, the exhaust valve is closed 8°-10°after the piston reaches the TDC position. An important phenomenon in the valve timing diagram is the angle of overlap.

Angle of Overlap :

The angle of overlap is the angle at which both the inlet valve and the exhaust valves remain open. Thus it can be seen that from the diagram the angle of overlap during slow speed is 5+8=13. The crank position at which ignition occurs is also indicated in the valve timing diagram. The ignition is provided 38°-40°before TDC during compression.

Valve Timing of Diesel Engine (CI)

|

IVO- Inlet Valve Open

|

10 -25 degree before TDC |

|

IVC- Inlet Valve Close

|

30-50 degree after BDC |

|

EVO- Exhaust Valve Opens

|

30-45 degree before BDC |

|

EVC- Exhaust Valve Close

|

15-30 degree after TDC |

|

FIS –

Fuel Injection start |

10-15 degree before TDC |

|

FIC –

Fuel Injection Close |

15-25 degree after TDC |

Very informative

ReplyDeleteGood information

ReplyDelete